High Quality Grain Extruder Soya Bean Bulking Machine For Corn Wheat

High Quality Grain Extruder Soya Bean Bulking Machine For Corn Wheat

Product Introduction:

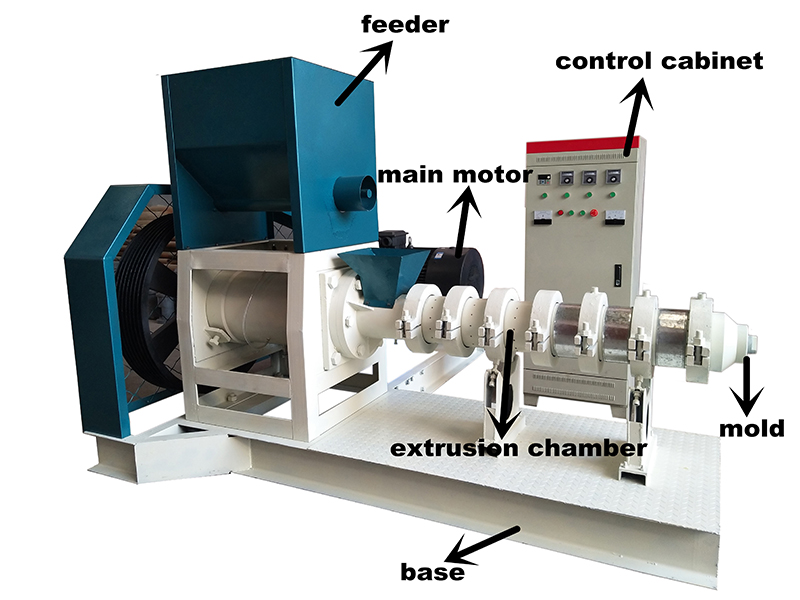

The DGP series of large and medium-sized dry feed extruder is carefully designed by adopting the advantages of domestic and foreign models and integrating a number of technological innovations. This machine adopts a combined main shaft, which can be adapted to the puffing processing of different materials and processing whole corn and soybeans.

The supporting facilities are simple and the operation and maintenance are convenient. The main motor can be Siemens to ensure product quality. The processing conditions of the dry extruder and the wet extruder are easily interchangeable, and the screw sleeve adopts an inlaid alloy steel bar structure, which has a longer service life.

It is widely used in extruded soybean, corn, suckling pig feed and other livestock and poultry feed, rice bran preservation, cotton meal, castor meal detoxification treatment, it is an ideal tool for feed processing enterprises.

Specification:

Advantages:

(1). The Full fat soybean extruder machine uses modular spindle, can be adapted to different materials Extruding processing, whole grain corn and soybean processing facilities is simple, easy operation and maintenance.

(2). novel design, high output, stable operation, the main components is heat treated special alloy material refined, with a high degree of wear resistance, long life and other characteristics.

(3). Extruding (whole corn) raw materials, and easy operation and maintenance, suitable for small feed mill and the majority of farmers' special use.

(4). The screw and sleeves using an inlaid alloy strip structure, longer life.

(5). The Full fat soybean extruder machine Widely used in expansion of soybean, corn, suckling pig feed materials and other livestock and poultry feed, rice bran preservation, cottonseed meal, castor meal detoxification, it is the ideal choice tool for feed processing enterprises.

Detailed Images:

Spare parts

![]()

Working Process:

* The screw sleeve and screw are made of a special high-temperature resistant alloy just now. They are formed by heat treatment.They are equipped with a unique pressurized die device to ensure the output and quality of the feed; and are equipped with an electric heating device to increase the boronization rate of the feed.

* The main motor adopts high-quality Y series three-phase motor to ensure strong power.

* The speed-adjustable feeding device is more convenient to operate, feeds evenly, and prevents material jams.

* The discharging template is easy to replace. If you need feed with different diameters, you only need to change the hole template. Ensure that the feed is clean and hygienic, which is conducive to protein denaturation and starch gelatinization, and is easy to absorb. Generally, the use of extruded floating fish feed saves 8%-15% of feed than powder or pellet feed.

Raw Material demand of Fish Feed Pellet Machine:

1).Raw materials can be: Corn, Wheat, Soybean, Grain, Bone powder, etc.

2).Raw materials need grind into 60-80Mesh.

3).Raw materials moisture content: 20-30%.

4).Diameter of Final Pellets Can be: 0.9-12mm.

5). Length of the pellets can be adjustable by control the cutting knife.

Package & Delivery:

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Ms. Lory Lu

Phone: +86 135 9245 8082

E-mail: info@zzagii.com

Whatsapp:+86 135 9245 8082

Add: No. 99-1 Jingsan Road, Zhengzhou, Henan, 450000, China