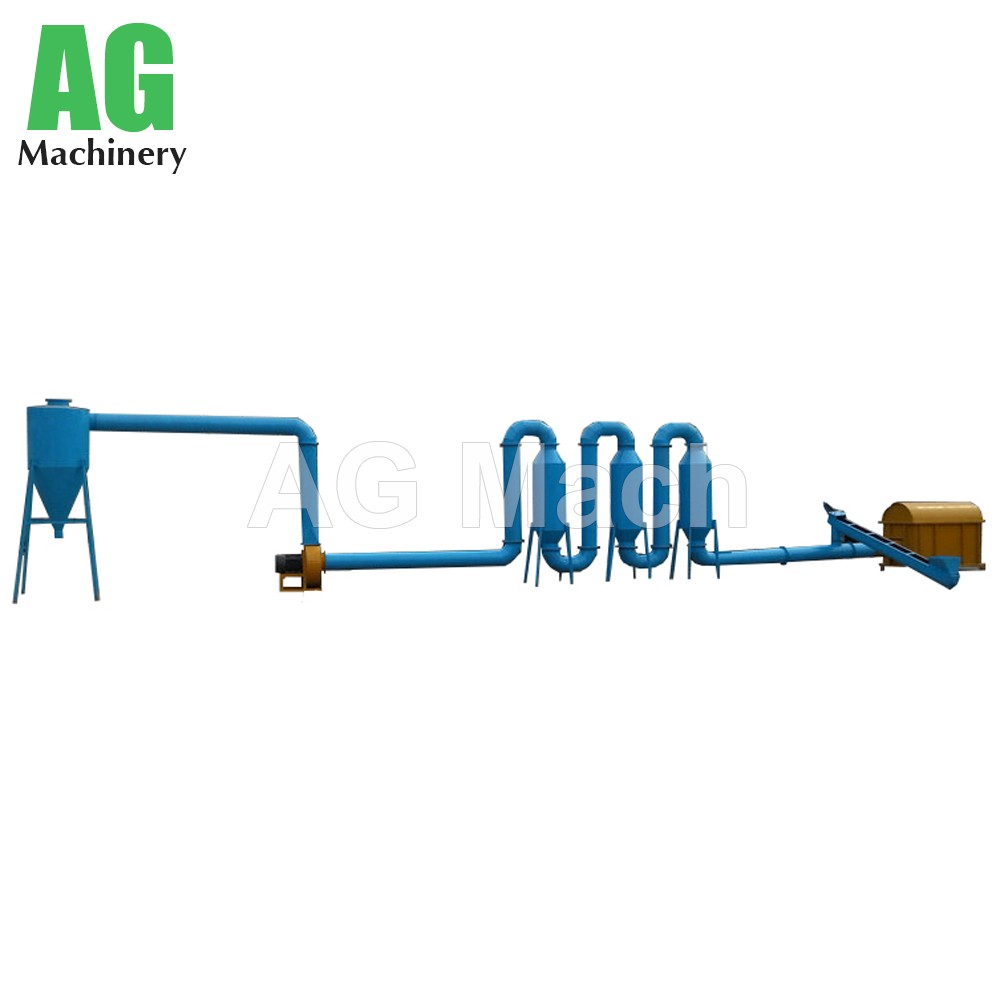

Industrial Dryer Machine Air Flow Dryer Wood Dryer Sawdust Drying Equipment

Introduction of biomass sawdust dryer:

The pipeline sawdust dryer machine is suitable for drying raw material with moisture content less than 20-25%. If the moisture content of raw material is higher than that, it will need several times of drying to achieve the requested moisture for further briquetting or pelletizing process.

It is suitable for drying sensitive material like sawdust, rice hull, milled wheat straw, milled cotton / corn stalks and so on.

It is made up of heat stove, tube, impulse jar, function tube, fan, and cyclone separator.

It can reduce moisture from 40-45% to 8-12%.

Fuel for the furnace: wood waste, coal. Waste oil and so on.

Industrial Dryer Machine Air Flow Dryer Wood Dryer Sawdust Drying Equipment

Introduction of biomass sawdust dryer:

The pipeline sawdust dryer machine is suitable for drying raw material with moisture content less than 20-25%.

If the moisture content of raw material is higher than that, it will need several times of drying to achieve the

requested moisture for further briquetting or pelletizing process.

It is suitable for drying sensitive material like sawdust, rice hull, milled wheat straw, milled cotton / corn stalks and so on.

It is made up of heat stove, tube, impulse jar, function tube, fan, and cyclone separator.

It can reduce moisture from 40-45% to 8-12%.

Fuel for the furnace: wood waste, coal. Waste oil and so on.

Specification:

| Technical Parameters | |||

|---|---|---|---|

| Model | HGJ-219 | HGJ-325A | HGJ-325B |

| Initial Moisture | 25%-30% | 25%-30% | 25%-30% |

| Final Moisture | 10%-15% | 10%-15% | 10%-15% |

| Main Power | 4kw | 5.5kw | 7.5 kw |

| Drying Speed | 300-400 kg/h | 600-800 kg/h | 800-1000 kg/h |

| Pipe Diameter | 219mm | 325mm | 325mm |

| Dimension | 8*2.19*3.8m | 13*3.25*4.2m | 13*3.25*4.2m |

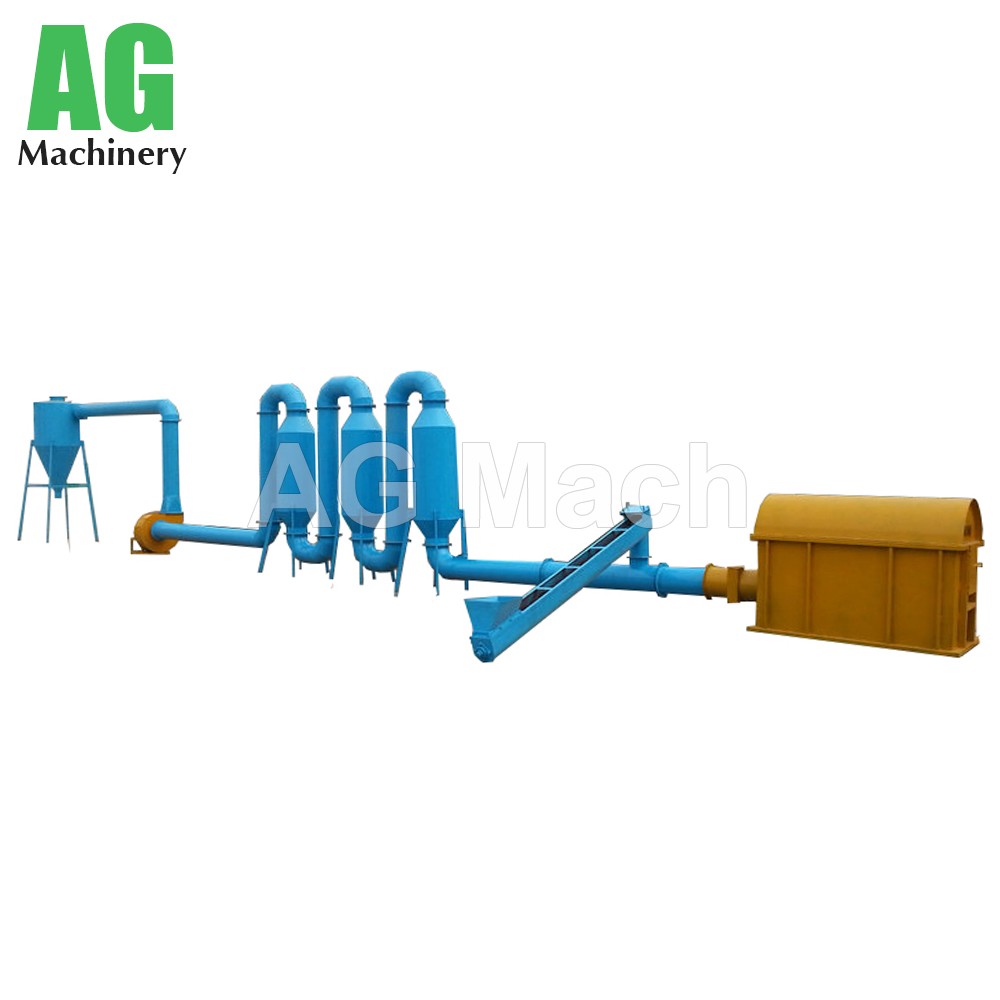

Working Principle

Sawdust dryer include: heat furnace, the feed mouth, rotating cylinder, filter tube, material conveying pipe, the cooling tube and the discharge port.

There is a feeding mouth between heat furnace and rotating cylinder.The rotating cylinder has a stir-frying lamina.There is a baffle between rotating

cylinder and

the filter tube,which also has a hole.The filter tube was connected with therotating cylinder at one end and materials at the other end.There is a baffle

in the filter tube and a slagging whole at the bottom.The cooling tube was connected with the material conveying pipe at one end and the discharge port

at the other end.

As a result of the above-mentioned structure, so the sawdust can be fully dried in the rotating cylinder and the sawdust can be fully spread again before

delivering into the material conveying pipe.The impurity can be blocked by the baffle,so the quality of the sawdust can be guaranteed when it is in the material

conveying pipe.Sawdust is ebullience fluidizd after the action of the blowpipe and the cylindrical vessel.The utility model has a simple structure, easy to use and so on.

Packing & Delivery

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Ms. Lory Lu

Phone: +86 135 9245 8082

E-mail: info@zzagii.com

Whatsapp:+86 135 9245 8082

Add: No. 99-1 Jingsan Road, Zhengzhou, Henan, 450000, China